Model Indentification:

JMK 80 AL PP TF TF PP

1 2 3 4 5 6 7

| Item | Description | Material | Item | Description | Material |

| 1 | Model | JMK | 5 | Diaphragm | TF -PTF EST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM GE-Geolast PU-Polyurethane |

| 2 | In/Outlet | 06=1/4” 10=3/8” 15=1/2” 20=3/4” 25=1” 40=1.5” 50=2” 80=3” 100=4” | 6 | Valve Ball | TF -PTF EST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM SS-Stainless Steel 304 LL-Stainless Steel 316 CM-Ceramic |

| 3 | Center Black | AL-Aluminum PP-Polypropylene SS-Stainless Steel | 7 | Valve Seat | TF -PTF EST -Santoprene HY-Polyether Rubber VT-VITON BN-NBR EP-EPDM SS-Stainless Steel 304 LL-Stainless Steel 316 PP-Polypropylene |

| 4 | Pump Body | PP-Polypropylen eKV -PVDF PM-POM AL-Aluminum SS-Stainless Steel 304LL-Stainless Steel 316AC-Cast Iron TF -PTFE | |||

| Technical Parameters: | ||

| Max.Suction lift [mwc] | dry | 5 |

| wet | 8 | |

| Max.Solids passage [mm] | 9.4 | |

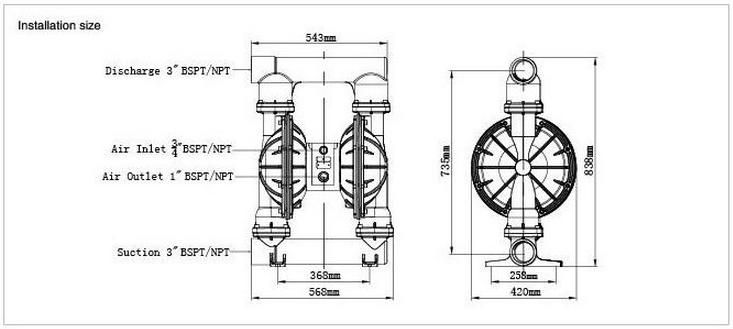

| Suction and discharge size[in] | 3" | |

| Air Inout[in] | 3/4" | |

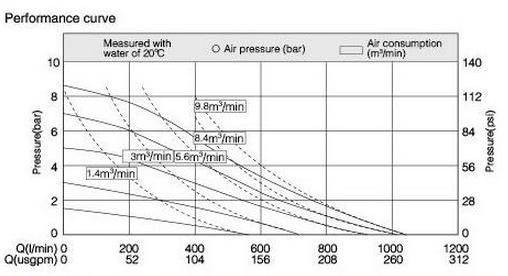

| Max.flow [l/min] | 1060 | |

| Max.head [m] | 84 | |

| Max presure [bar] | 8.4 | |

| Max.Temperature | 135℃ | |

| Material quality: | ||

| Pumpbody: SS304, SS316, SS316L | ||

| Diaphragm: Santoprene, Hytrel, Teflon, Viton, EPDM, Buna-N | ||

| Valve ball: PTFE,Santoprene, Hytrel, Teflon, Viton, Stainless steel, Ceramic | ||

| Valve seat: PTFE,Santoprene, Hytrel, Teflon, Viton, Stainless steel | ||

| Center block: PP, Aluminum, Stainless steel | ||

| Weight | ||

| SUS304 pump: 120 kgs | ||

| SUS316 pump: 120 kgs |

Product Description:

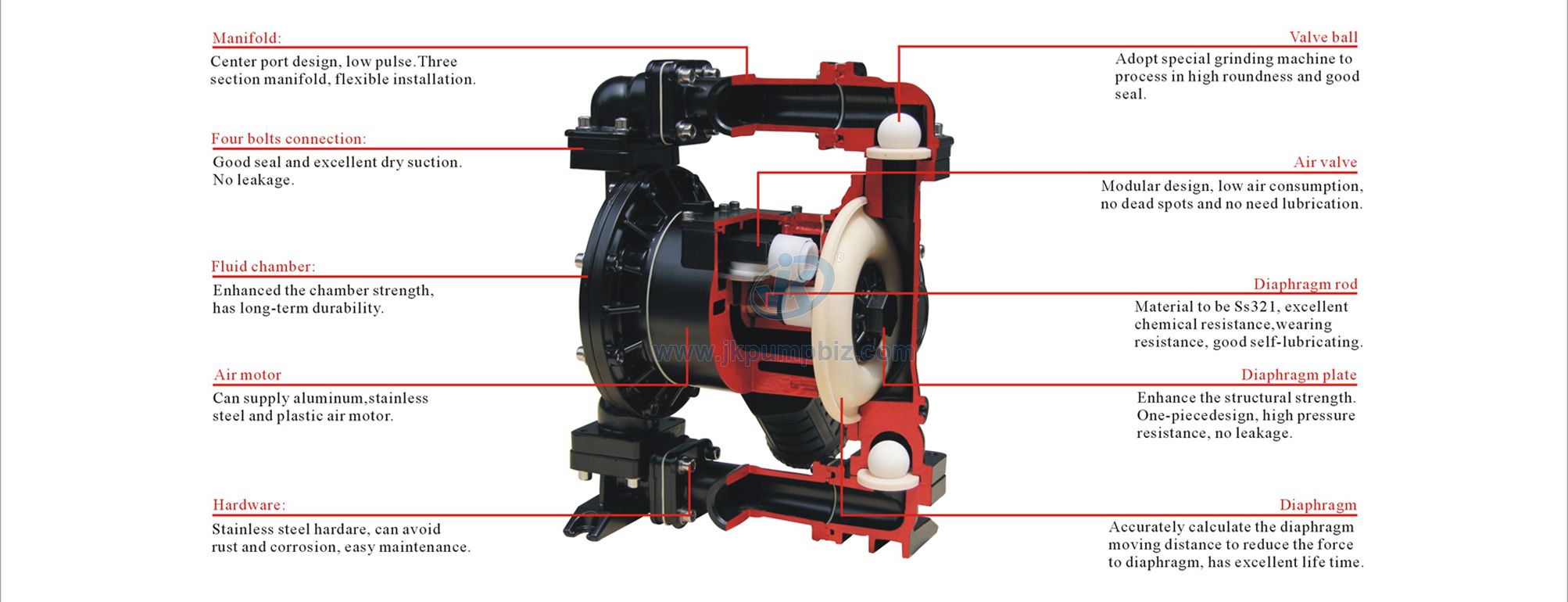

1. The series of JMK diaphragm pumps are highly engineered diaphragm pumps,delivering a smooth,reliable flow for all circumstances.the new air valves design guarantees a perfect,non-stalling operation,even at low pressure.the air valves do not need any lubrication.thanks to their unique design,the pumps are able to handle very abrasive and or viscous products;

2. Sulfuric acid Diaphragm Pump uses compressed air as the power source and uses the diaphragm inside the cylinder body to agitate and do work to achieve the purpose of conveying various media;

3. The diaphragm pumps will run dry indefinitely without damage;

4. Air operated double diaphragm Pump can transport medium: pneumatic diaphragm pump is applicable to transport a variety of corrosive, with particles of liquid, and high tolerance, volatile, flammable, highly toxic liquid,etc;

5. The product is manufacturer under ISO9001:2015,CE certified quality system;

6. 1 year for main structure;

7.Diaphragm pump application:

Oil & Gas:Natural gas fields,Offshore platform requirement,Diesel fuel transfer,Spill clean-up ,Salt water transfer/disposal ,Flame knockout;

Ceramics:Casting machines,Day tank transfer ,Mold filling/cleaning ,Recirculation;

Chemical processing;

Construction:Portable utility,Oil transfer,Fuel transfer,Site dewatering

Features and advantages:

1.Light weight,Easy installation and maintenance;

2.Performs on -demand in remote locations;

3.Extremely portable for multi -locations;

4.Little air waste and pulsation, high capacity and performance;

5.Can run dry without pump damage;

6.No air lubrication necessary;

7.The fluid transport is extremely extensive,Can convey acid,alkali,strong organic solvents and other fluid;

8.High temperature resistant, corrosion resistant;